Belt dryers are widely used in industry, mainly for drying small pieces of materials and fibrous materials. The characteristic of a belt dryer is that it has no dust. The drying process is completed in a fully enclosed environment, avoiding dust leakage. Suitable for materials that do not allow fragmentation. The dried material is placed on a conveyor belt in a stationary state for drying, and the material will not be damaged. The finished product has good quality. The dried materials all have the same drying time, which ensures consistent color and uniform moisture content of the materials.

The existing belt dryers have single-layer and multi-layer designs. Hot air penetrates the single-layer and multi-layer materials upwards or downwards, and after heat and mass transfer, the humid air is directly discharged into the atmosphere or partially reused. Driven by the transmission mechanism, the mesh belt conveying materials slowly moves inside the dryer box, gradually drying the wet materials. The existing belt conveyor technology has the following problems in actual production:

(1) The intake temperature is low, usually at room temperature, and the heating energy consumption is high;

(2) The utilization of hot air through mesh belts is insufficient, resulting in high exhaust temperatures, high exhaust gas recovery costs, and serious energy waste;

(3) Low utilization of return water and high energy consumption for heating steam;

(4) Poor adaptability to viscous materials and difficulty in solving adhesive tape problems, which affect product quality;

(5) It is difficult to control the drying temperature of different materials and the degree of automation is low.

The chain plate belt dryer is a new type of belt dryer developed and produced by Baide Drying based on years of practical experience and advanced technology of similar products at home and abroad. It overcomes and compensates for the shortcomings of existing equipment in the actual use of some materials, making the structure of the belt dryer more complete and reasonable, with a wider range of applications, stable and convenient operation, and high thermal efficiency. Baide Drying has developed and produced a series of specialized belt dryers for different materials, including vegetable dehydration machine, Chinese herbal medicine decoction machine, food seasoning machine, food stir fry machine, pigment machine, plastic particle drying and heat treatment machine, etc.

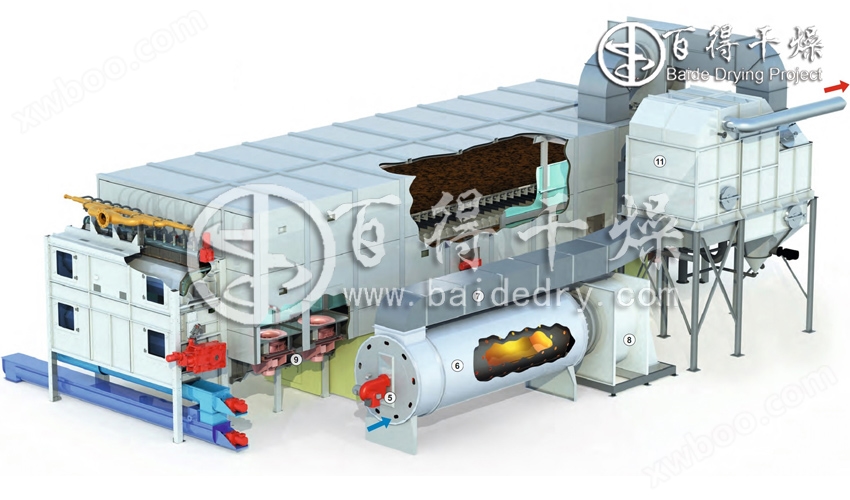

Structure diagram of chain plate belt dryer equipment

Working principle of chain plate belt dryer

Wet materials are evenly distributed on the adjustable speed mesh belt through suitable feeding devices. During drying, hot air flows through the gaps between the mesh belt and the material from top to bottom, making each surface of the dried material a heating surface. This significantly increases the heat exchange contact area between the material and the hot air, shortening the evaporation and diffusion distance of moisture inside the material. Therefore, it can perform extremely effective drying operations. The independent lateral circulation of the hot air unit enhances the penetration of hot air, and makes temperature and air volume control more flexible and convenient, thus having a wider adaptability to materials of different types and properties.

Performance characteristics of chain plate belt dryer

(1) The new type of chain plate mesh belt dryer consists of a wind powered water removal fabric system, mesh belt transmission system, hot air circulation drying system, heating system, and automatic control system. It can adapt to large-scale production, with significant energy-saving effects, high production efficiency, good product hygiene conditions, and quality.

(2) The built-in hot air circulation system of the mesh belt dryer consists of a circulation drying unit that integrates a circulation fan, an airflow heating device, a uniform air box, and a return air box. All hot air circulation systems and mesh conveyor systems are installed inside a sealed drying oven. Hot air circulates through the material layer multiple times in the drying chamber, allowing the dried material to absorb the heat of the hot air multiple times, fully utilizing the thermal energy and saving energy; The hot air duct is located in the drying room, fully utilizing the radiation heat of the heat source, increasing the air flow heating rate in the drying room, and reducing energy consumption.

(3) The new chain plate mesh belt dryer is equipped with a mesh belt cleaning and cleaning structure, which improves the adaptability of the belt machine to highly viscous materials, making the conveyor belt that enters the fabric again clean and free of impurities, ensuring the quality of the dried product.

(4) The new chain plate mesh belt dryer is equipped with guiding devices on both sides of the conveyor system to correct the left and right deviation of the conveyor belt during operation and ensure the normal conveying of the conveyor system.

(5) The new type of chain plate mesh belt dryer adopts a fully enclosed, hot air circulation, built-in heat exchanger, automatic temperature control in separate compartments, and exhaust heat recovery and utilization system, which can save more than 20% energy compared to conventional belt machines.

(6) The high-efficiency and energy-saving new belt dryer is not only widely used for drying fruits and dehydrated vegetables, but also can be promoted and applied in industries such as food, light industry, and chemical industry. On the basis of standardized products, while emphasizing their specificity, Baide Drying has developed and produced a series of specialized belt dryers for different materials: fruits and vegetables, traditional Chinese medicine decoction pieces, nuts and stir fried goods, dyes and pigments, puffed feed, plastic pellets and pellet furnace materials, etc.

Chain plate belt dryer cleaning and washing device

(1) The adjustment parameters of the new chain plate mesh belt dryer are also quite diverse, so it also has significant production flexibility. In order to ensure production capacity, there should be a margin in the selection of heat sources, supply fans or exhaust fans.

(2) The uniformity of the fabric in the new chain plate mesh belt dryer is very important. Because in the belt dryer, both the mesh belt and the material layer play a role in evenly distributing air. If the fabric is uneven, a hot air short circuit will occur, causing uneven drying of the material on the mesh belt.

(3) In order to facilitate uniform airflow based on the flow performance of the hot air itself, the dynamic pressure Pd of the hot air inlet duct should be less than 50Pa. If possible, increase the volume of the box for the hot air inlet as much as possible, which is also beneficial for air distribution.

(4) For each drying unit, it is advisable to achieve uniform air flow both horizontally and vertically, using methods such as orifice plate uniform air flow, guide plate uniform air flow, and return air uniform air flow.

(5) After a long period of use, the conveyor chain will wear and elongate. There must be a mechanism to adjust the position of the bearings at both ends of the conveyor chain, which should be adjusted regularly to keep the chain in a reasonable working state.

(6) The main drive shaft of the conveyor belt must be in front of the conveying direction, so that the load-bearing conveyor belt section is always in a taut state.

Production photos of chain plate belt dryer